(TC-C002) PTFE – PTFE –SS Braiding

August 9, 2018

(TC-C004) PTFE –Almylar Screening- PTFE

August 9, 2018(TC-C003) PTFE –POLYMIDE-COPPER SCREENING- PTFE

Technical Details

| Design Standard | As per JSS 51038, ANSI MC 96.1, IS 8784 & IEC 60584.3 |

| Conductor | K/J/T/E/N/KCB/KCA/KX/EX/TX/NX/TX/JX/SC/RC or as per Picture No 1 |

| Conductor Type | Solid wire / Flexible |

| No of Pair | Single / Multi pair |

| Conductor Size | AWG 34 AWG to 14 AWG or Variant as per customer specifications, Refer Size Chart Picture No.2 |

| Insulation | Wrapped & Sintered PTFE |

| Core Identification | As per Picture No 1 |

| Isolator | Polyimide tape |

| Screening | Bare Copper Wire/Nickel Plated Copper/Silver Plated Copper with covering >65 % Coverage area |

| Outer Sheath | Wrapped & Sintered PTFE |

| Outer Colour | As per Picture No. 1 |

| Accuracy | As per Picture No. 1 |

| Resistance | As per ANSI MC 96.1 |

| Temperature Range | -65 Deg C to 260 Deg C |

Applications:

- Used for measuring the temperature

- For carry the mV signal from sensor to panel

- In Laboratory for calibration of high temperature furnaces

- Industry plant, power station, refineries, petrochemical plants etc.

- In Defence, Aerospace, Pharma, Fertilizer, Glass , Steel & Sponge, Cement, Nuclear & many more sectors.

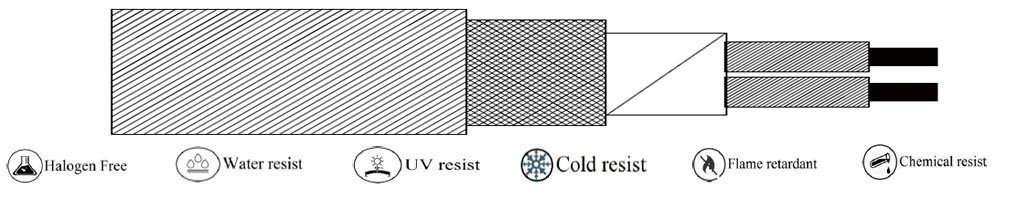

Features:

- Flame & Fire Resistance

- Temperature range up to 260 Deg C

- Excellent protection to external electromagnetic interference

- Halogen Free & Low smoke

- Enhance thermal, electrical & fire properties

- Good Flexibility

- Excellent Dielectric Strength

- Excellent Insulation resistance

- Good abrasion resistance

- Chemical & Oil Resistance